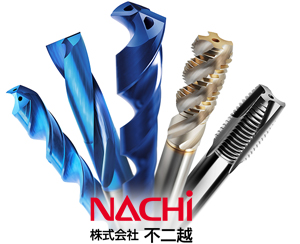

Nachi Cutting Tools

HSS and solid carbide machining tools ??? universal, robust and economic

NACHI’s drills, taps, and end mills work extremely productively, and have proved to be highly wear-resistant and care for longest service time, thanks to sophisticated substrates, innovative cutting geometries, and high-quality coatings. They convince with utmost process reliability, also under difficult conditions. This is advantageous for professional craftsmen and in all segments of industrial machining.

NACHI offers a comprehensive range of HSS and solid carbide tools for all machining tasks.

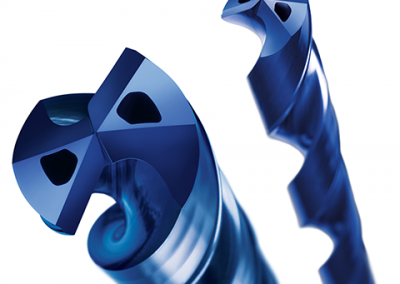

Drills

The wide range of high-performance drilling tools supplied by NACHI, with diameters of 0.2 to 32mm, offers solutions for every application. High-speed steel or solid carbide drills can be used for a wide range of metals, alloys, and plastics highly efficient and productive. For this, they are made of selected substrates, and feature optimized geometries plus carefully matched coatings. Even for special metalworking tasks, NACHI can provide efficient drilling tools out of its standard portfolio.

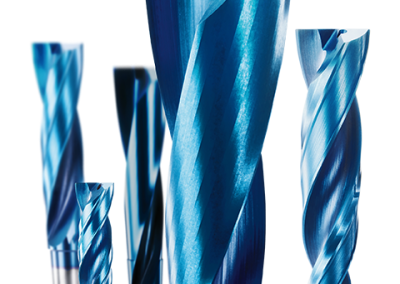

End mills

NACHI offers the most various types of end mills for a wide application range to machine numerous materials ??? from aluminium to titanium, through mild steels and carbon steels up to corrosion-proof chromium steel alloys. Thanks to convincing features such as diamond-like coatings (DLC), fine and coarse flute spacings, ball and corner radius, drilling face geometry or types in the micro-diameter range, the end mills can be used efficiently in production lines, and also in mold & toolmaking.